Manufacturing

Our Manufacturing

Production

Production

The state-of-the-art infrastructure located in Kolkata and Umbergaon has stringent manufacturing standards, producing 2 million writing instruments every day. Both our Kolkata and Umbergaon facilities are ISO 9001:2015 and SA 8000 certified.

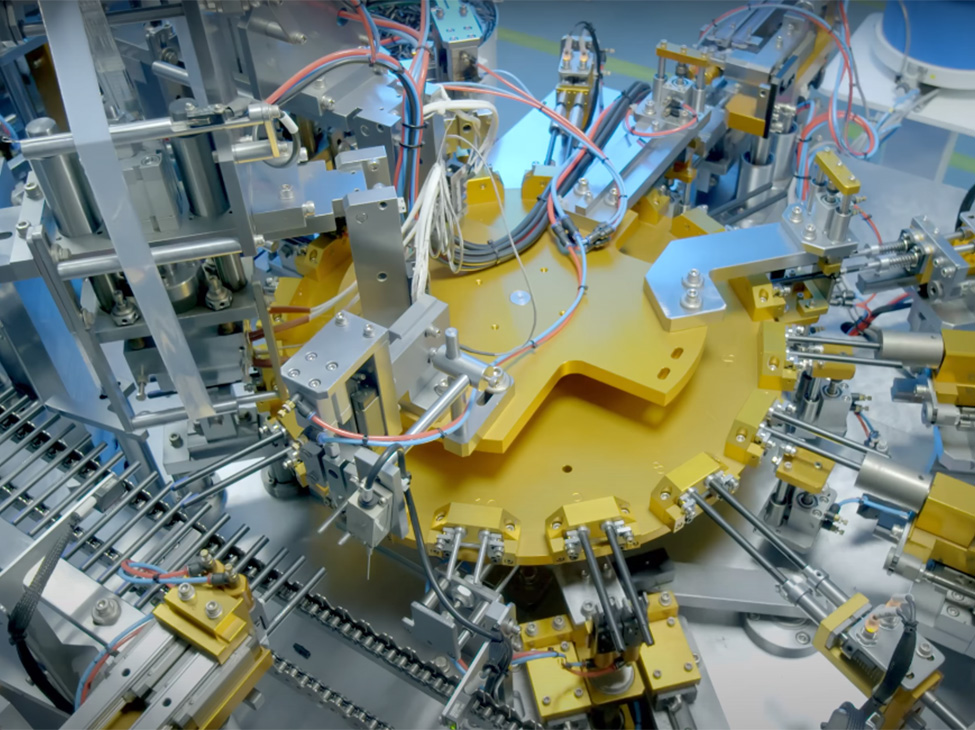

The manufacturing facilities are marked by a high degree of automation and integration supported by cutting edge R & D process, discipline and certification. Linc uses the latest technology like Injection Moulding Machines, Extruder Machines, and Screen-Printing Machines.

Our assembly machines are fully automated to ensure maximum efficiency and the highest quality. Linc takes pride in its seamless production process.

Technology

Technology

Injection moulding and extrusion are two common manufacturing processes used in the production of our pens. Injection moulding involves injecting molten material into a mold cavity, where it solidifies and takes the shape of the mold. Extrusion, on the other hand, involves forcing a heated material through a die to create a continuous shape.

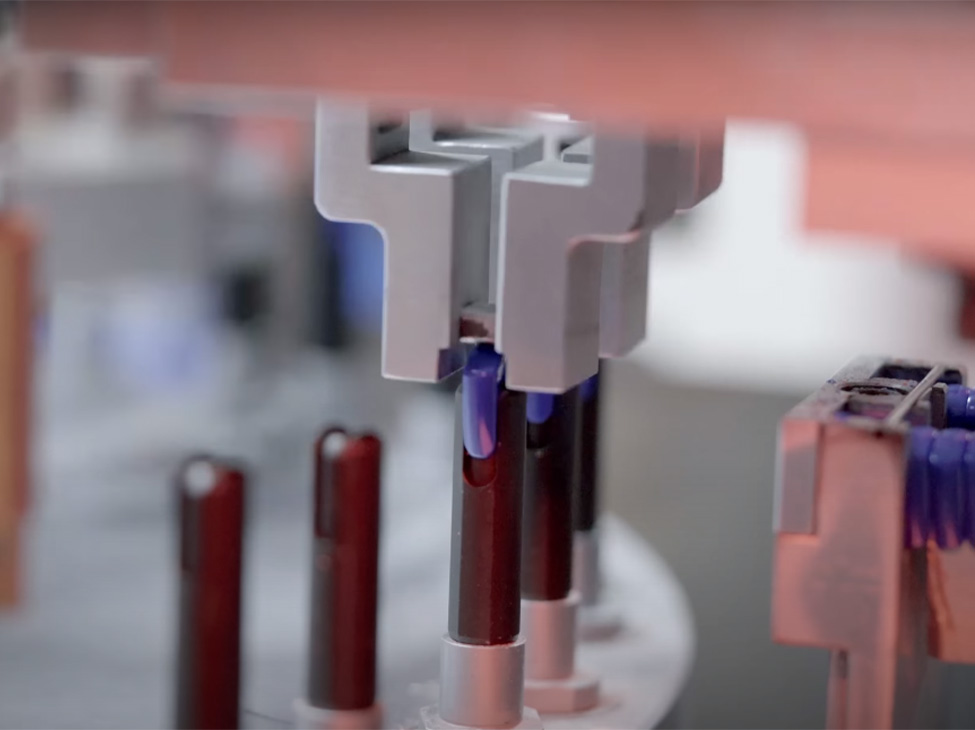

In pen manufacturing, injection moulding is used to produce pen barrels and caps. The molten material is injected into the mould, which is designed to create the desired shape and texture of the pen barrel or cap. Once the material has cooled and solidified, the mould is opened and the newly formed pen component is removed. Extrusion, on the other hand, is often used to produce the ink cartridges or tubes that hold the pen ink.

The heated material is pushed through a die, which gives it the desired shape and size. Once the material has cooled and hardened, it is cut to the appropriate length for use in the pen. Overall, injection molding and extrusion are both efficient and effective ways to produce high-quality pens on a large scale.

Assembly

Assembly

Assembly is a critical stage in the pen manufacturing process, as it is where all the individual components of the pen are brought together to form a functional writing instrument. In this stage, we assemble several components in a specific sequence to create a pen that writes well and looks aesthetically pleasing.

The importance of assembly in pen manufacturing lies in its ability to ensure that the pen is properly put together, functions smoothly, and meets the required quality standards. The primary goal of any pen is to write, and the assembly process ensures that all the components come together to create a writing instrument that performs its function effectively.

During assembly, the ink cartridge is inserted into the barrel, the nib is attached to the feed, and the cap is secured to the barrel, all of which are essential for the pen to function correctly. During the assembly process, each component of the pen is inspected for defects and damage, ensuring that only the best quality components are used in the final product.

This quality control process helps to identify any problems early on and prevent defective pens from being sent to the market, reducing the likelihood of product recalls and customer complaints. The assembly process is also important for ensuring that our manufacturing process runs smoothly and efficiently. This is particularly important in a highly competitive industry like ours, where efficiency can make a significant difference in profitability.